Steel floor types

Tecnaria connectors can be used for both new floors and for the consolidation of existing steel floors.

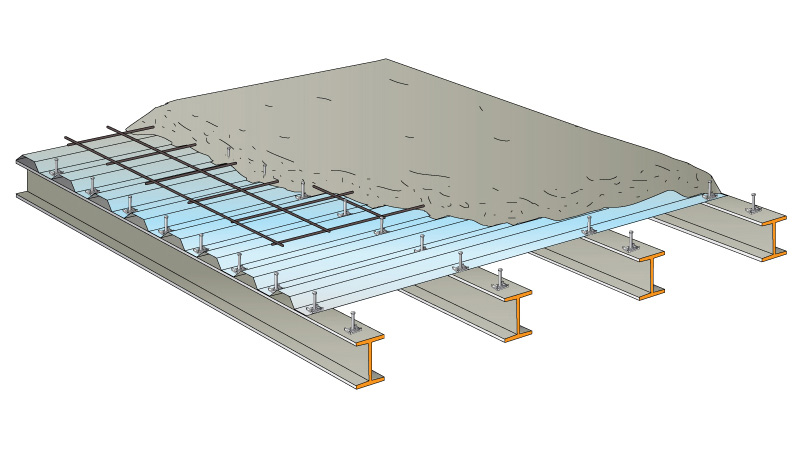

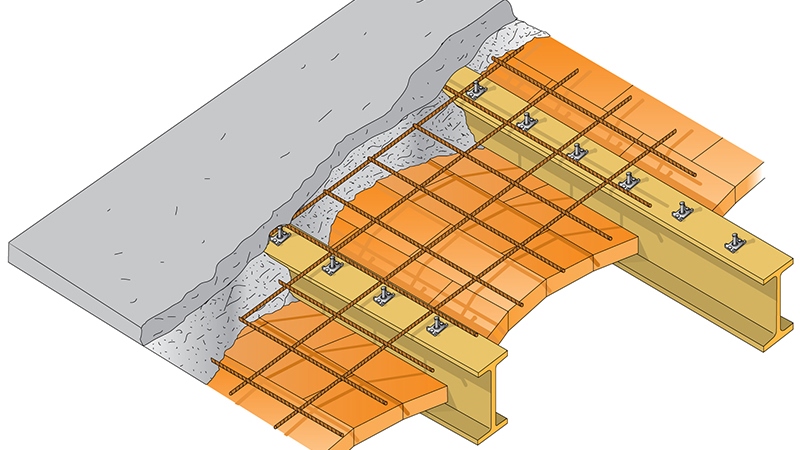

CONSOLIDATION OF NEW STEEL FLOORS

The construction of new floors using the composite steel-concrete method is very beneficial in many situations, both as far as the practicality of the works, and the performance levels that can be reached with reduced thicknesses.

THE COMPONENTS FOR STEEL FLOOR CONSOLIDATION

CONCRETE

Structural concretes of minimum class C25/30 are normally used, with a minimum thickness above the steel deck of no less than 5 cm. No technical installation must be inserted in the slab. Lightweight concrete can also be used. A mesh reinforcement or equivalent reinforcement must be inserted. The technique proposed is well suited to prefabricated joist floors (Bausta), while it is difficult for Sap or Varese floors, which have concrete joists of very small sizes.

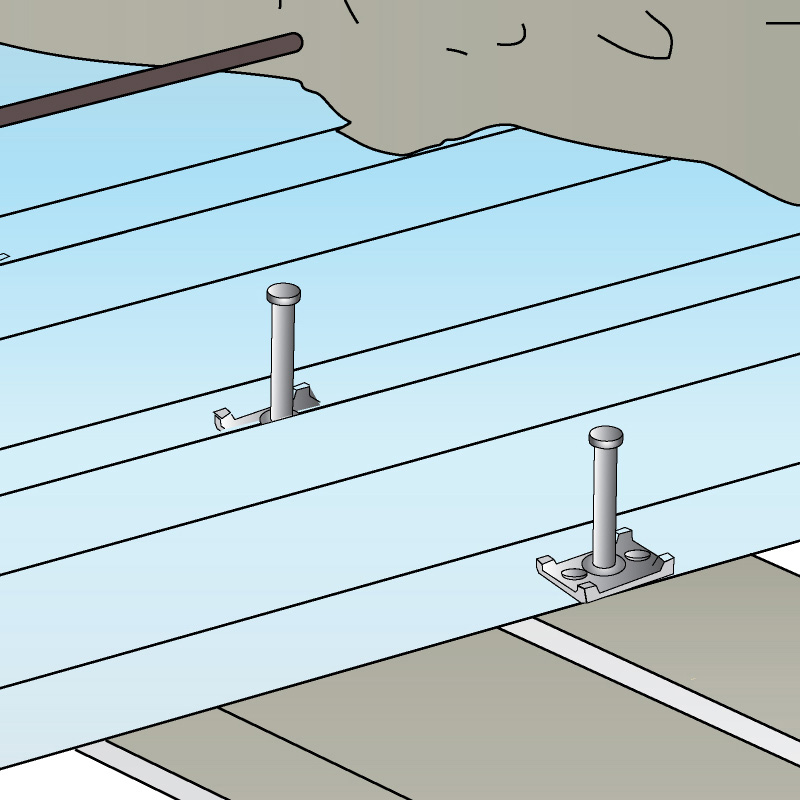

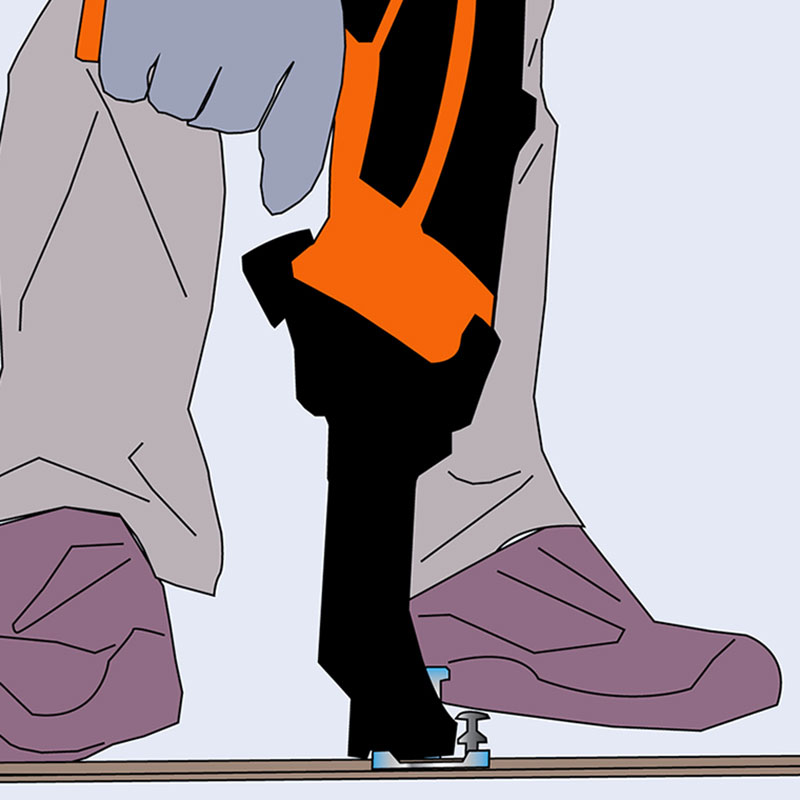

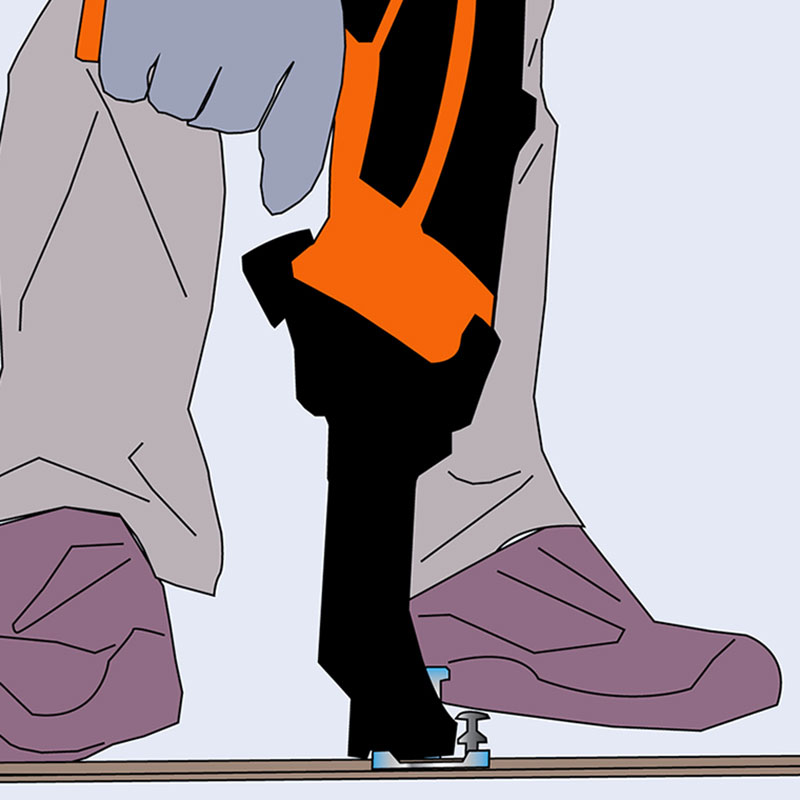

P560 NAIL GUN

The nails are fastened with a SPIT P560 nail gun which can be hired from Tecnaria. Once the profiled sheeting is in position over the steel beam, it is sufficient to shoot the high-strength nails supplied with the connector. The nail gun is easy to use on site. Other types of nailers must not be used.

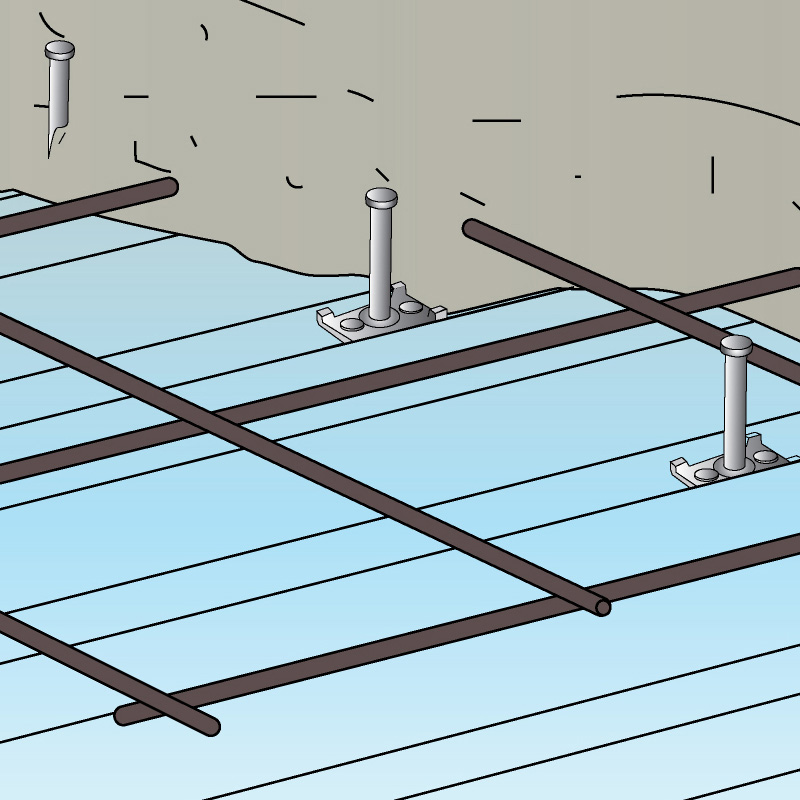

ELECTROWELDED MESH

A suitably sized mesh reinforcement is always laid in the slab. Normally, a Ø 8 mm, mesh 20×20 cm is placed in the middle of the slab. It is not necessary to fix the mesh to the connectors.

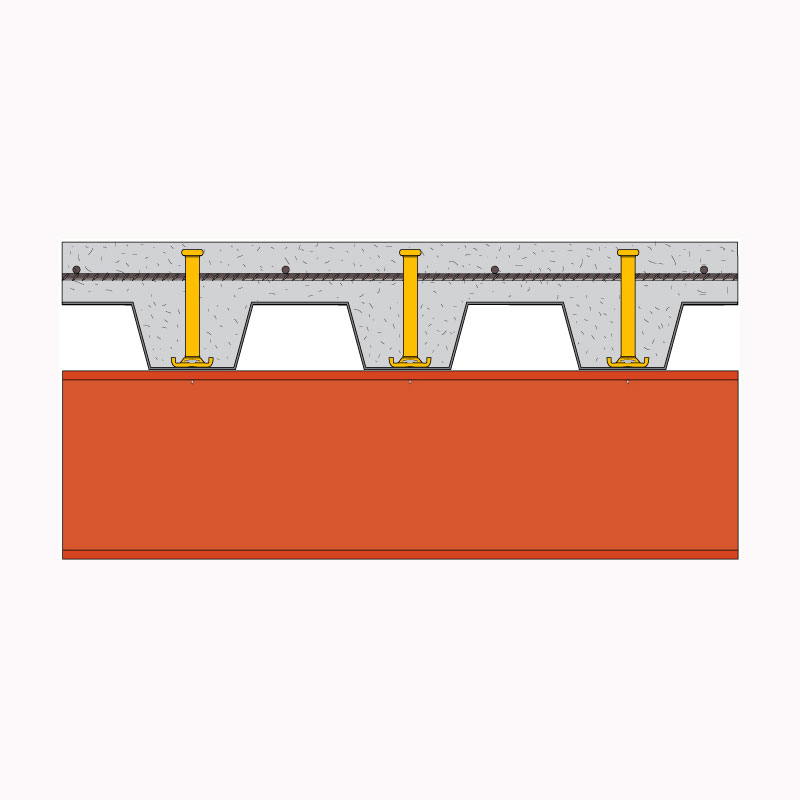

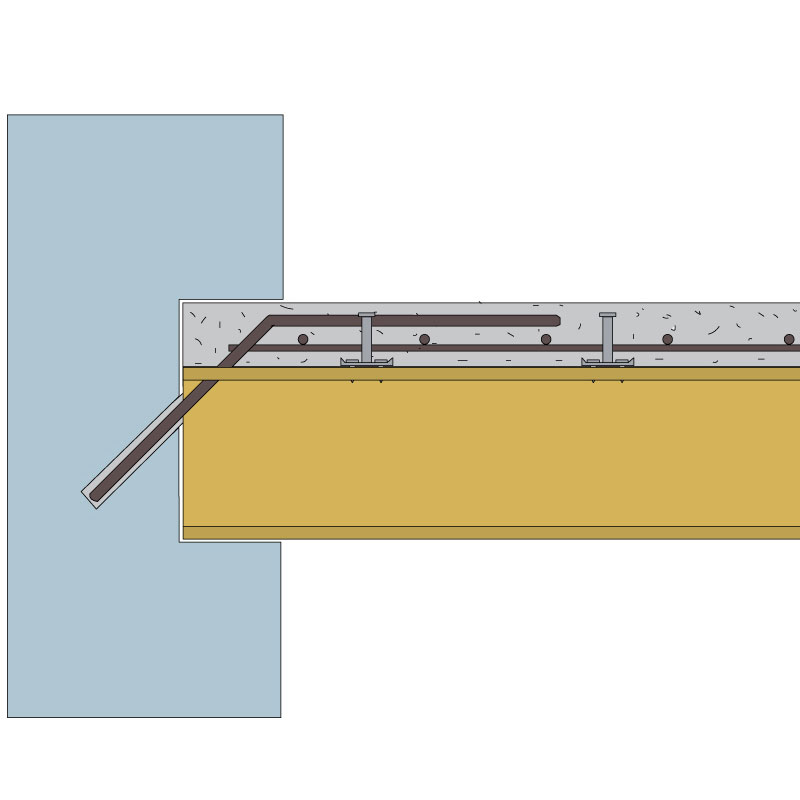

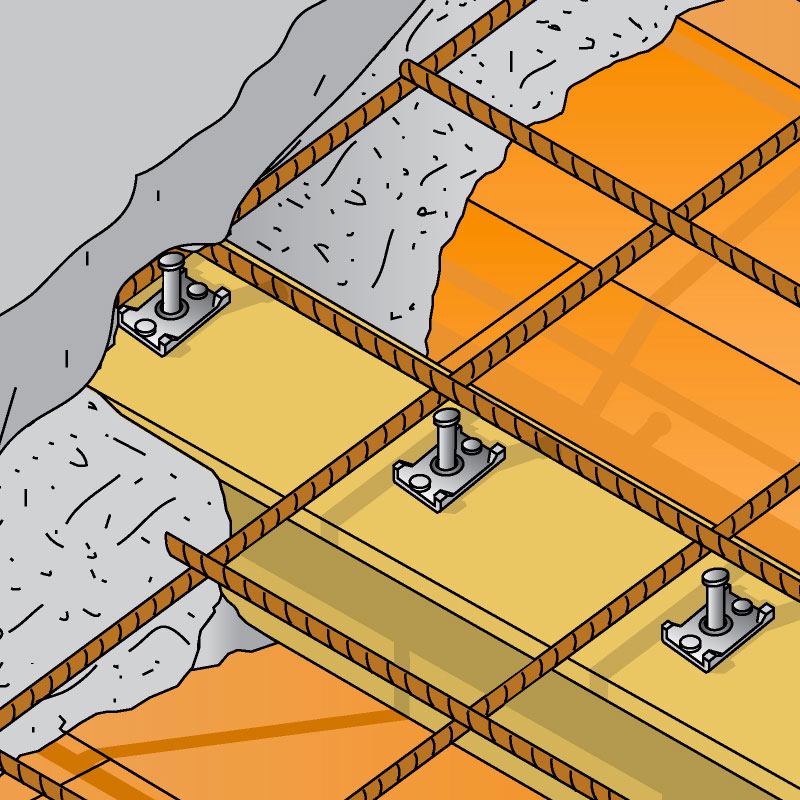

PROFILED SHEETING

Metal decking is generally laid on top of the beams. In order to fasten the connector, the sheeting must adhere correctly to the beam. A maximum of two sheets, with a total thickness of 2 mm, may be laid one on top of the other. Hi-Bond 55 sheets (or similar) are normally used, with fret height 55/60 mm. Hollow bricks or wood boarding can also be used as decking.

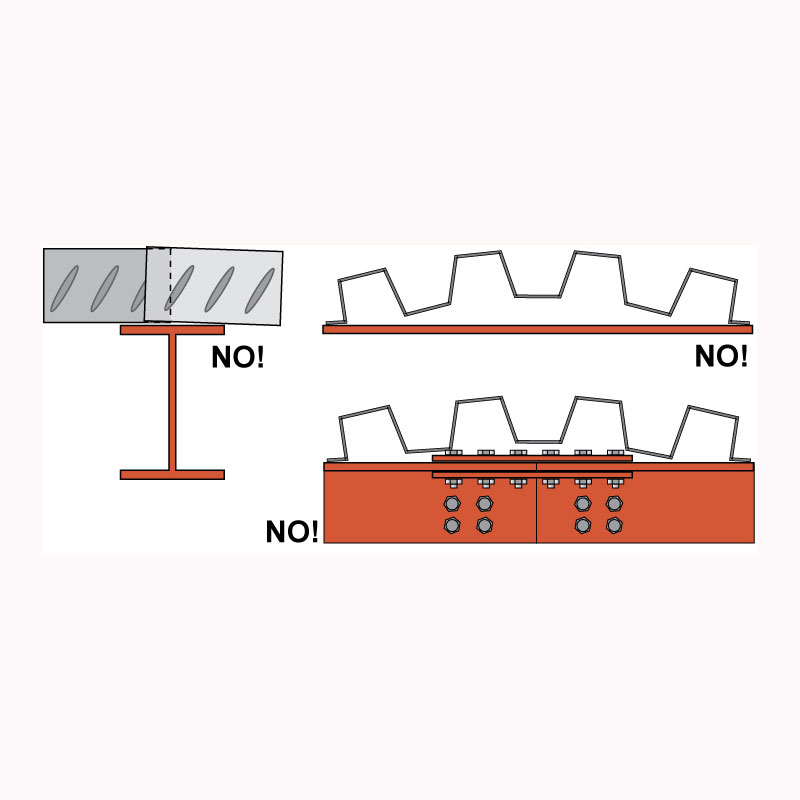

INSTALLATION OF PROFILED SHEETING

The connectors CANNOT be fixed where there is irregular overlapping of several layers of sheeting, on sheeting that does not adhere properly to the beam, or on bolted beams.

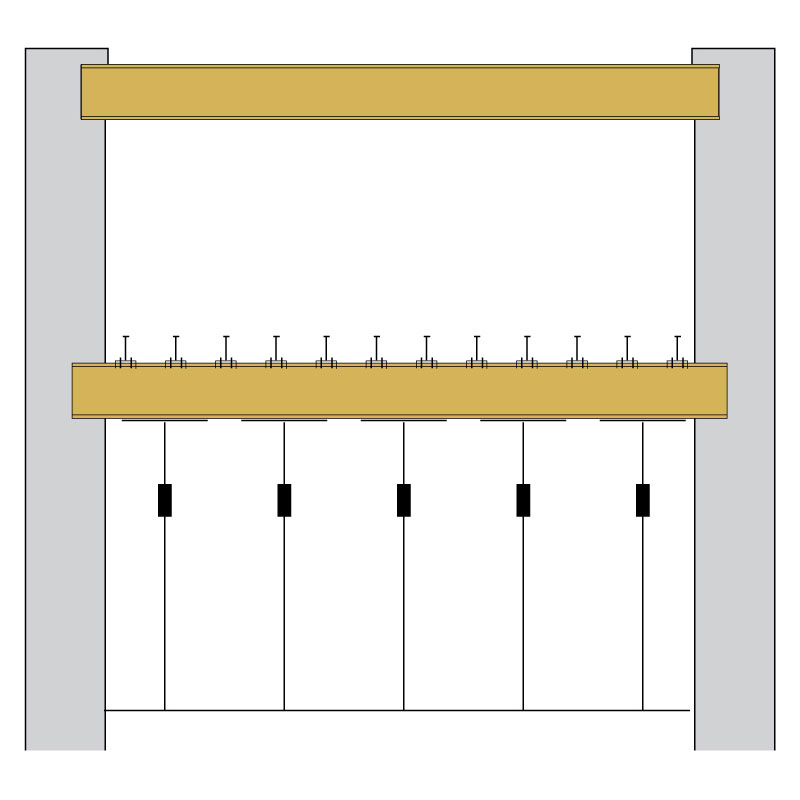

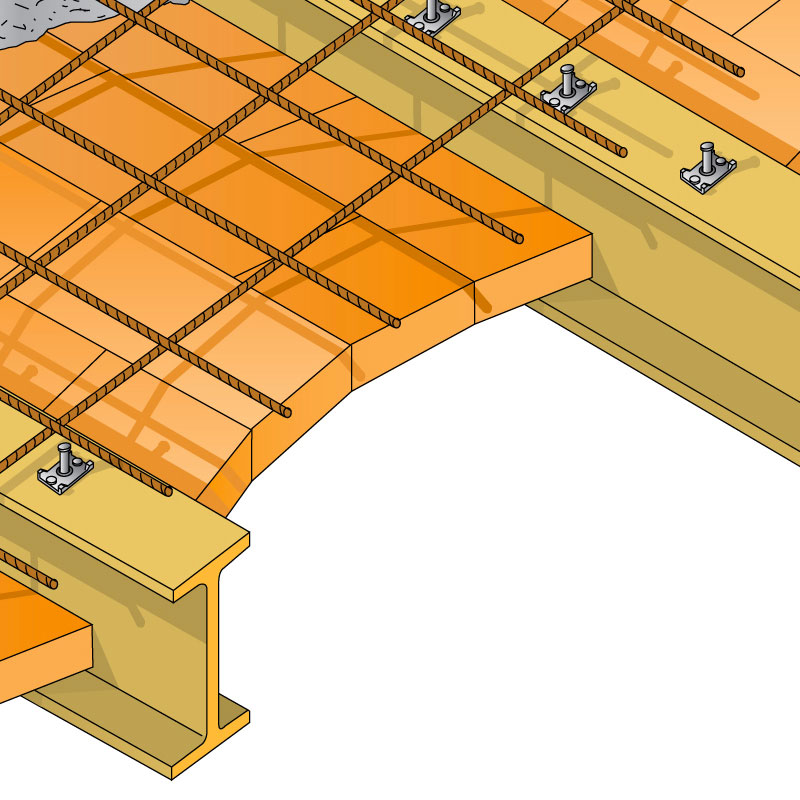

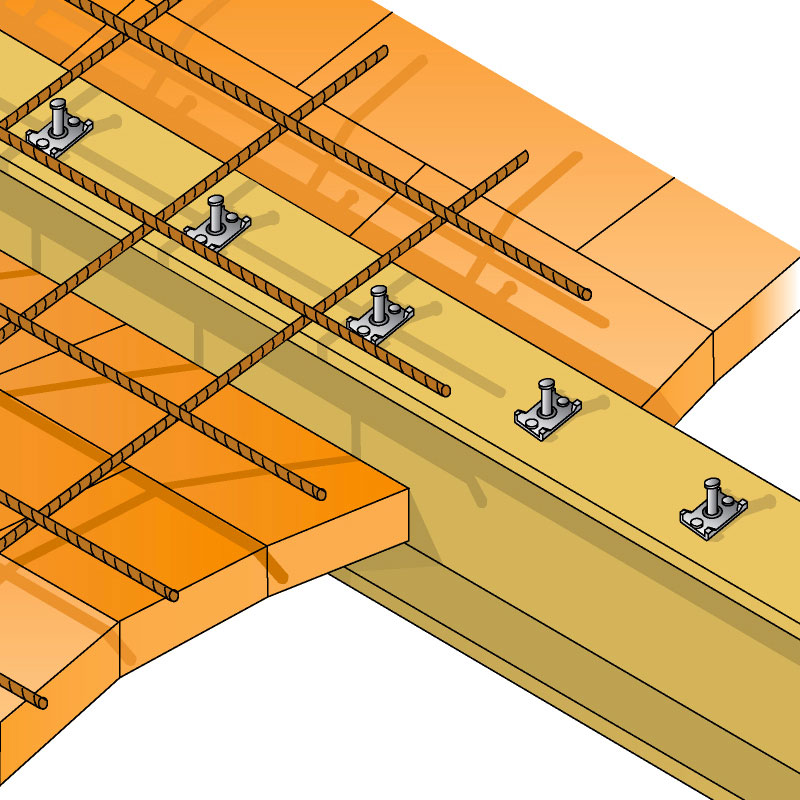

POSITIONING OF CONNECTORS

The number of connectors to be positioned is determined by calculation (on average about 3 to 5 elements per m²). They will be fixed closely spaced near the walls and more widely spaced in the centre of the beam.

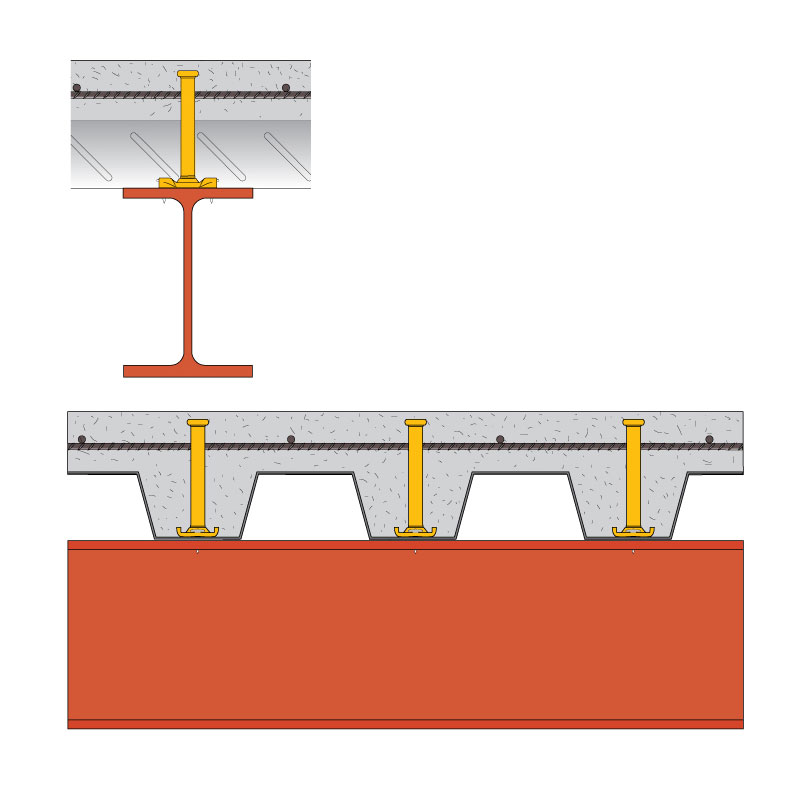

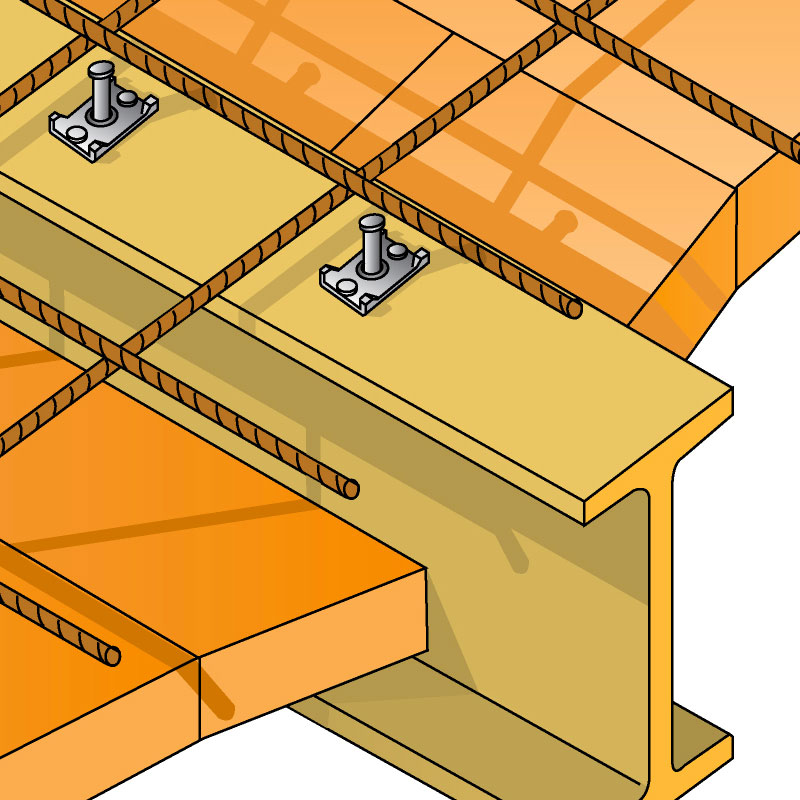

CTF CONNECTOR

The connector consists of a headed stud, inserted into a base plate into which two nails are inserted for fixing. The limited size makes it most suitable for use in floors not subject to high loads and for general restoration work where a great flexibility of use is required.

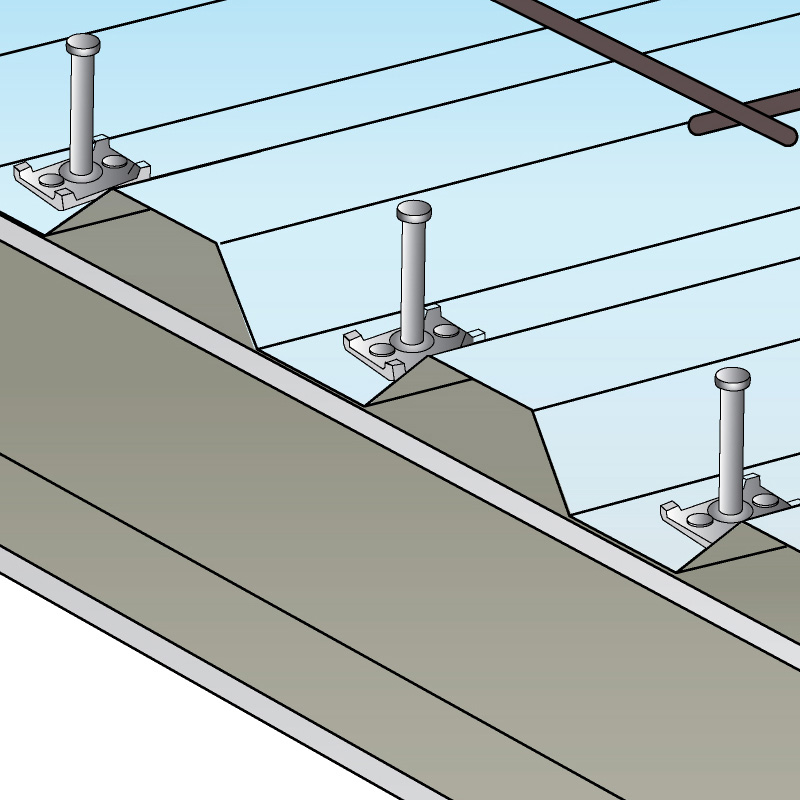

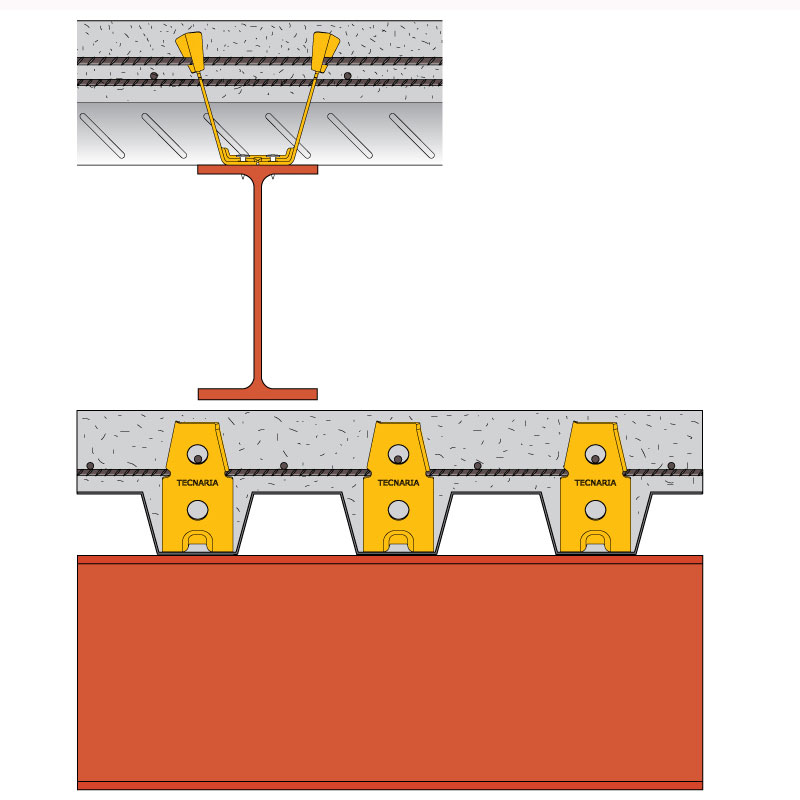

DIAPASON CONNECTORS

The DIAPASON connector is made of a galvanised plate 3 mm thick, shaped so as to obtain a base to be fixed with four nails to the steel beam and two wings to create a more effective connection with the concrete. This connector provides a high mechanical performance.

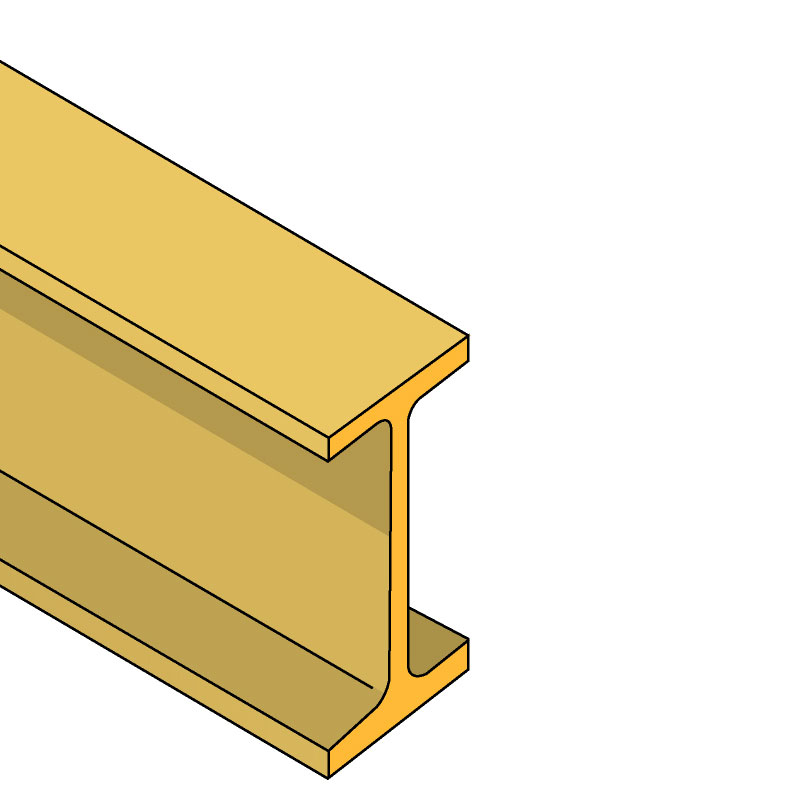

STEEL PROFILES

S235, S275 and S355 steel beams can be used, even when painted or hot-galvanised. The connectors can be fixed to profiles with a minimum flange thickness of 6 mm. The nails can also be fixed into solid steel.

FLOOR SHORING

Floors should be shored before the new casting takes place to achieve maximum efficiency of intervention. However, during the calculations it is also possible to allow for a floor without shoring.

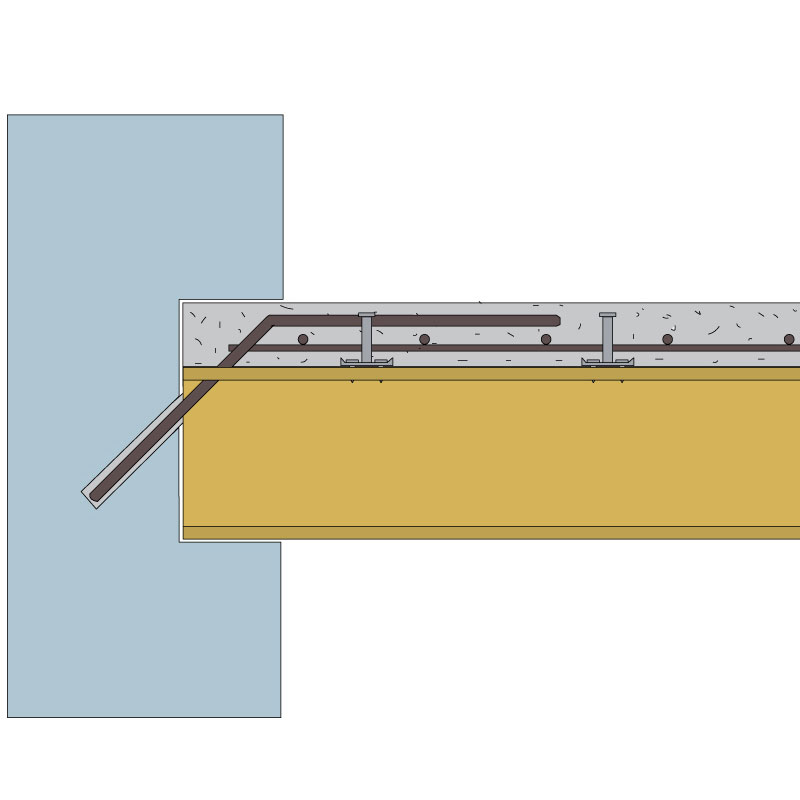

CONNECTION TO THE WALLS

If the existing floor does not have a perimeter beam resting on the walls, it is advisable to join the slab to the bearing walls round the perimeter of the floor. This precaution brings benefits in terms of stiffness and seismic resistance of the floor.

FIBRE REINFORCED CONCRETES

They are used when the thickness of the new layer must be limited to 20 or 30 mm, and when a reduction of the load is required. MINI CEM connector only.

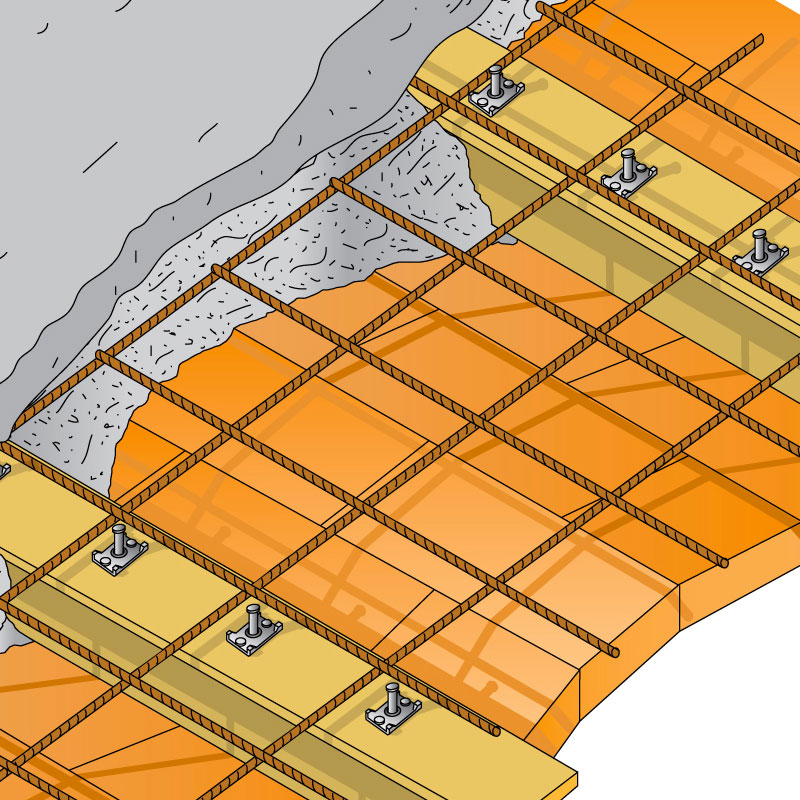

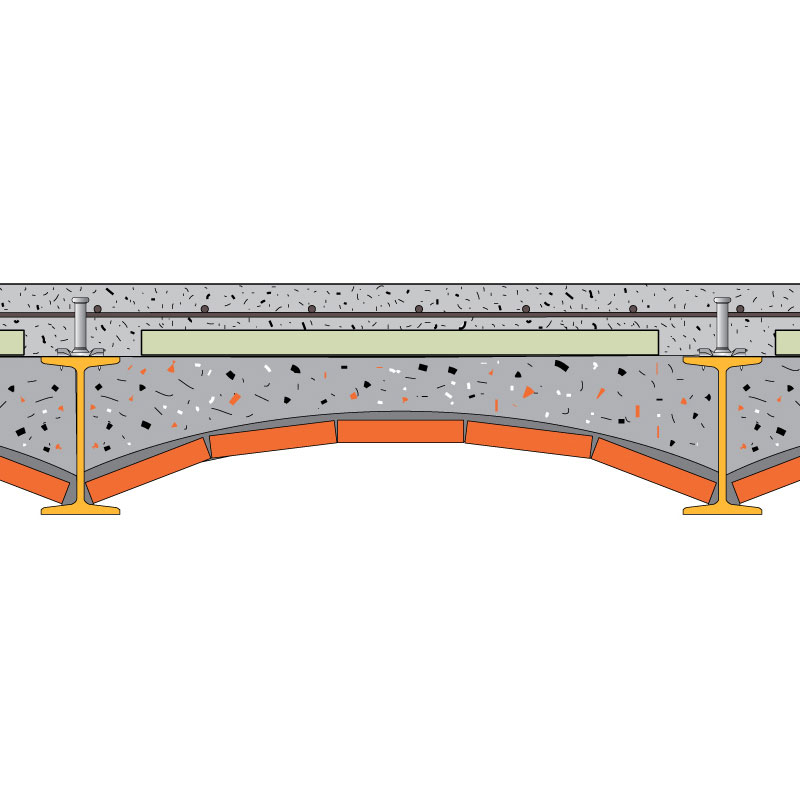

CONSOLIDATION OF EXISTING STEEL FLOORS

From the second half of the nineteenth century onwards, floors were frequently made using “double T-shaped” beams with brick arches, as an alternative to wood floors. The beams rested on the main walls with a spacing usually varying from 60 to 110 cm. The space between the beams was in filled with solid or hollow brick elements. A filling layer, often using waste material from the building site, was laid on top of the structure thus obtained, to level the surface of the floor and provide the bed for laying the floor finish. The consolidation of steel floors is recommended and always necessary for seismic reasons.

THE COMPONENTS

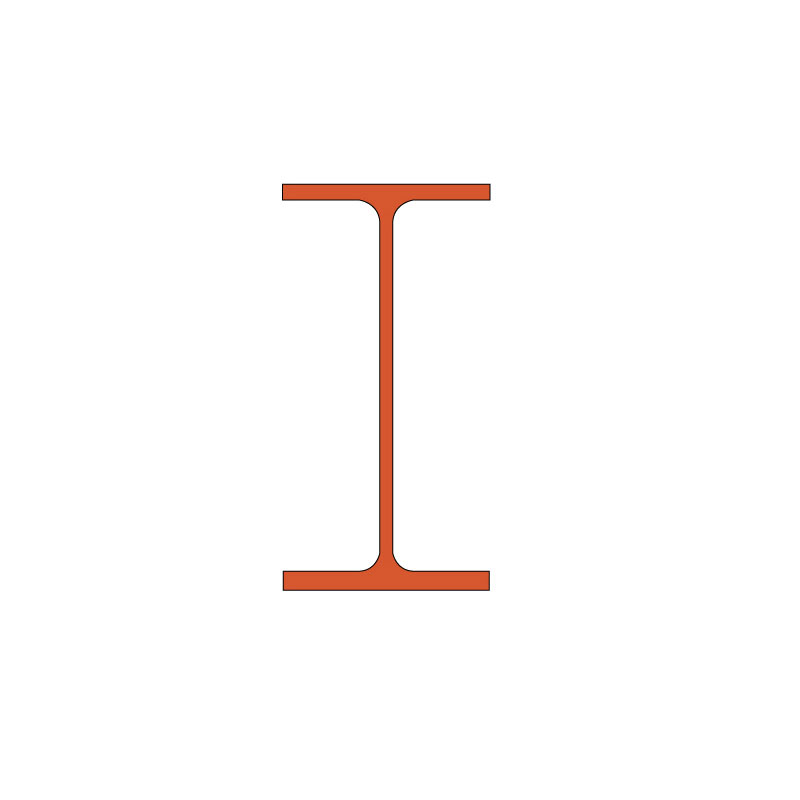

STEEL BEAMS

In the past, it was not common to use steel profiles with a standard geometry. It is therefore necessary to measure the section of the profile and know the characteristics of the steel. Normally rolled “I” beams (e.g. BBS profiles or Universal Beams) were used. These existing beams often cannot be welded due to their chemical composition. According to the technical manuals of the period the stress on the beams could vary from a minimum of 900 Kg/cm² to a maximum of 1200 Kg/cm².

CONCRETE

Structural concretes of minimum class C25/30 are normally used to make the load-bearing slab, with thickness no less than 5 cm. Technical installations cannot be inserted into the slab.

LIGHT STRUCTURAL CONCRETES

The use of lightweight concrete is recommended to reduce the dead load of the strengthened slab while maintaining its high mechanical strength. It is especially recommended for use in seismic areas.

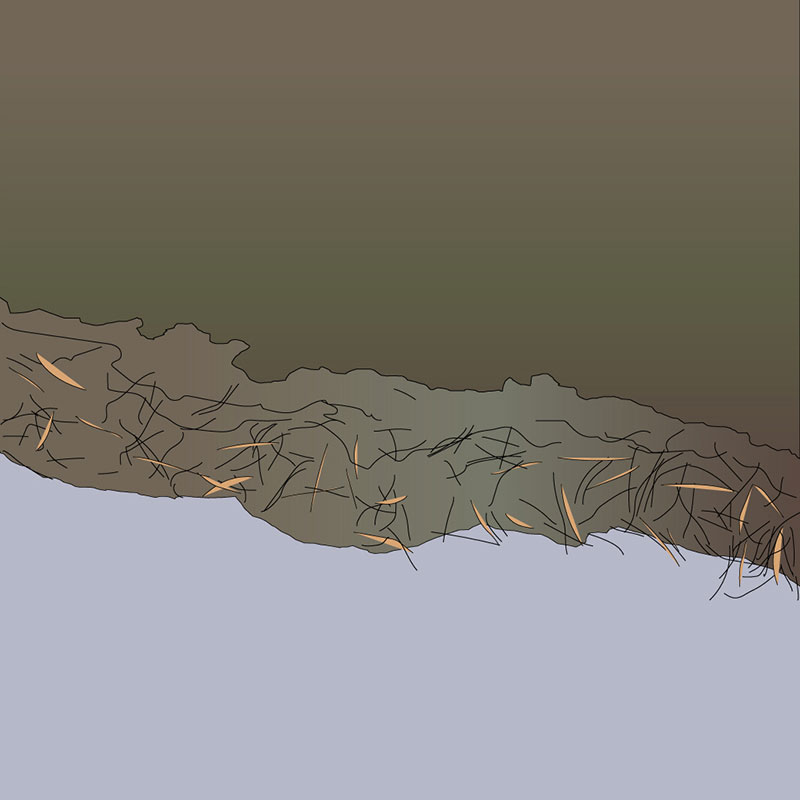

FLOOR BOARDS

The floor deck is normally composed of brick vaults or hollow bricks. Levelling was carried out with loose filler material. It is preferable to replace these heavy layers with aerated clay or polystyrene. The brick elements can be used as formwork for the subsequent casting if they are in good condition. Profiled sheeting may be used as an alternative.

ELECTROWELDED MESH

A suitably sized electrowelded mesh must always be laid in the slab. Normally 8 mm diameter, 20 x 20 cm mesh is used. It is not necessary to fix the mesh to the connectors.

CTF CONNECTORS

The connector consists of a headed stud, inserted into a base plate into which two nails are inserted for fixing.

The chemical composition of the existing iron beams, also hampered by the presence of dust, rust or mortar, makes it difficult, if not impossible, to weld metal elements. Fastening with TECNARIA connectors efficiently solves the problem, since nails penetrate directly into the steel. The simplicity of installation makes this the ideal system!

INSTALLATION

One of the main merits of the system is the rapid and safe way of fixing carried out with a nail gun which is available on hire. However, fixing the nail into the beam may create vibrations and this must be taken into account if there are elements that could be damaged (e.g. plaster ceilings). In these rare cases the connectors are welded.

POSITIONING OF CONNECTORS

The number of connectors to be positioned is determined by calculation (on average about 5 to 6 elements per m²). They will be fixed closely spaced near the walls and more widely spaced in the centre of the beam.

FLOOR SHORING

Floors should be shored before the new casting takes place to achieve maximum efficiency of intervention. However, during the calculations it is also possible to allow for a floor without shoring.

CONNECTION TO THE WALLS

If the existing floor does not have a perimeter beam resting on the walls, it is advisable to join the slab to the bearing walls round the perimeter of the floor. This precaution brings benefits in terms of stiffness and seismic resistance of the floor.

INSULATION

By adding a panel of rigid insulating material, the section of the composite steel-concrete beam will be increased without increasing the dead weight of the floor. Advantages are obtained in terms of strength, stiffness, and partly in thermal and acoustic insulation.